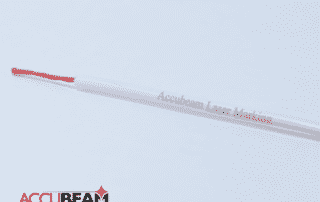

LASER MARKING

Accubeam Laser offers contract Laser Marking Services to a wide range of industries including Medical Device, Aerospace, Military, Automotive, Electronics, Promotional and much more. We eliminate heat affected zones through a cold marking process which enables us to mark on all metal types and most plastic and synthetic types while minimizing surface and component damage.

For a comprehensive list of Laser Marking capabilities refer to our Specifications Table below.

| Specifications | |

|---|---|

| Laser Types | CO2, YAG, Fiber, U/V |

| Materials | Polycarbonate (PC), Polyamide (PA), Polypropylene (PP), Liquid Crystal polymer (LCP), PVC, PBT , ABS, HDPE, Delrin, PET, Polyethylene (PE), Silicone, Nickel plating, Copper, Steel, Aluminum, Stainless Steel, Paper, Epoxy, Glass, Glass epoxy, Cation painting, Nonwoven fabric (PP/PE/PET) |

| Drawing Types | .dxf .ai .dwg .hpgl .jpg .bmp .tif & Gerber |

| Secondary Operations | Laser Cutting, Laser Engraving, Deep Engraving, CNC Machining, Precision Surface and Blanchard Grinding |

| Industry Focus | Medical, Aerospace, Military, Electronics, Automotive, Promotional, Industrial, Marine |

| Application Types | Identification (All Industry Types)

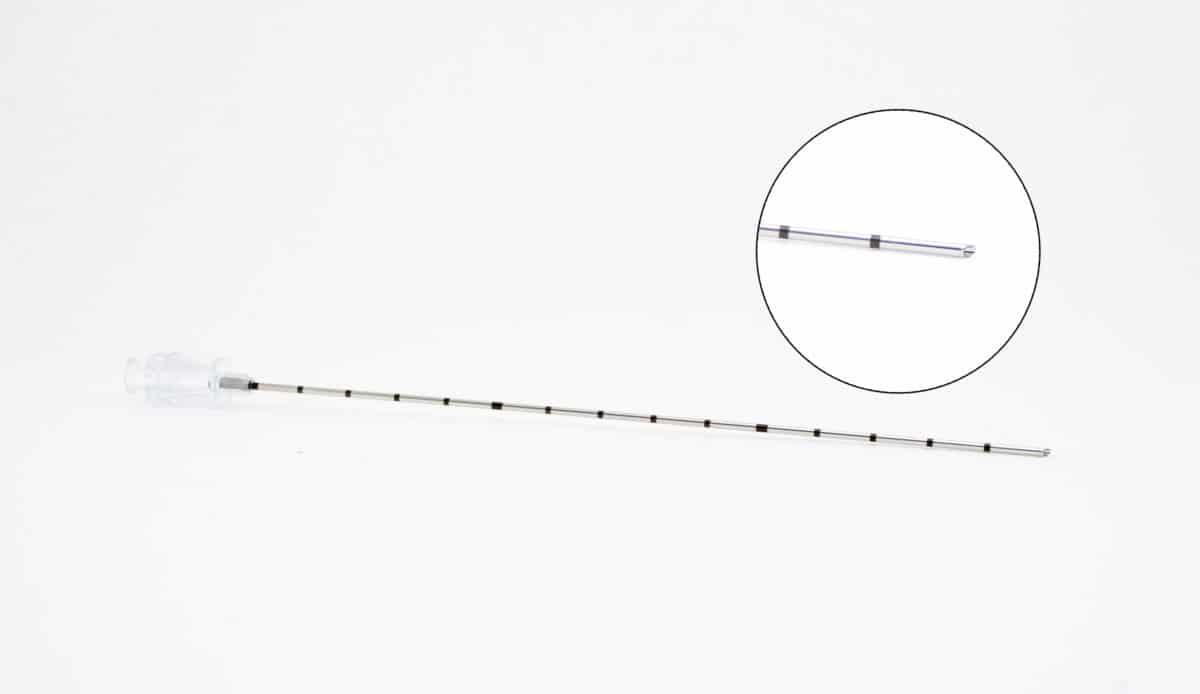

UID, UDI, Bar Codes, Lot Codes, 2D Data Matrix Automotive/Marine Cation-painted parts, Multicolor automotive relays, ECU PCBs, In-vehicle plastic parts, Switch covers, Terminals, Fuse holders, Windows Electronics Mobile device & accessories, Terminal block, Wafers , Crystal oscillators, Transparent cases, LED lights, Lead frames, IC packages Medical/Pharmaceutical Magnifying glasses, Masks, Electric toothbrushes, Medical tubing, Medicine bottles, Steel instruments, Protective eyeware Foods, Cosmetics Bottles, Caps, Tubes, Desiccant, Cases, Cartons, Packaging, Film |

What is Laser Marking?

Laser marking is a process by which a beam of focused light interacts with the surface material to change the color which in turns leaves a mark or contrast. There are different types of laser marks, but the most common are Annealing, Carbon Migration, Coloring and Foaming. The type of mark being applied depends on the surface material of the part, additives that may be in use with the material and any outer coatings that have been applied or will be applied after the mark is created.

Here at Accubeam we have extensive experience working with a wide array of materials, parts and industries to provide exacting solutions that meet or exceed our customer’s needs and specifications.

The phrase Laser Marking is sometimes used interchangeably with the terms Laser Engraving or Laser Etching. The applications however are very different. As described above, when you laser mark you are changing the surface with heat which changes the color of the material. When you laser etch or laser engrave, the material surface is physically being removed or vaporized, leaving a cavity. The difference between etching and engraving is fairly subjective based on the depth of the cavity but generally they are used interchangeably.

Laser marking can be performed on almost any material type. We say “almost any” because there are a few material types, Teflon for example, where changing the color is challenging. In those cases we have developed a special process to engrave the material and fill the cavity with an enamel to provide the color contrast like an actual laser mark.

![]()

Why Should I Consider Laser Marking?

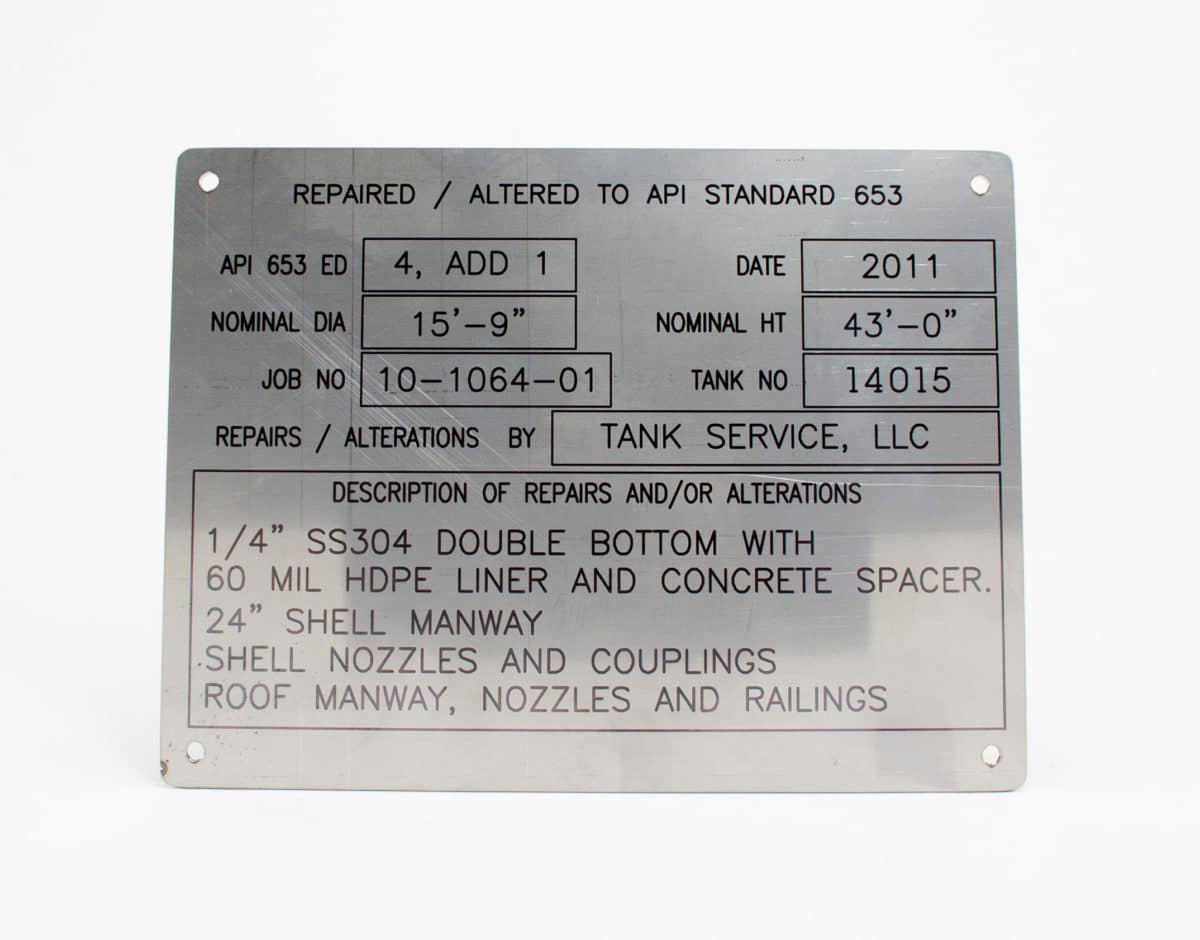

- The marks are permanently changing the color of the surface material not applying a layer of color that can come off over time.

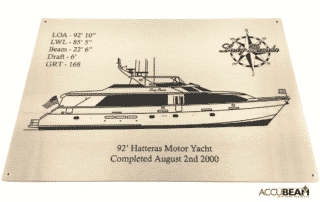

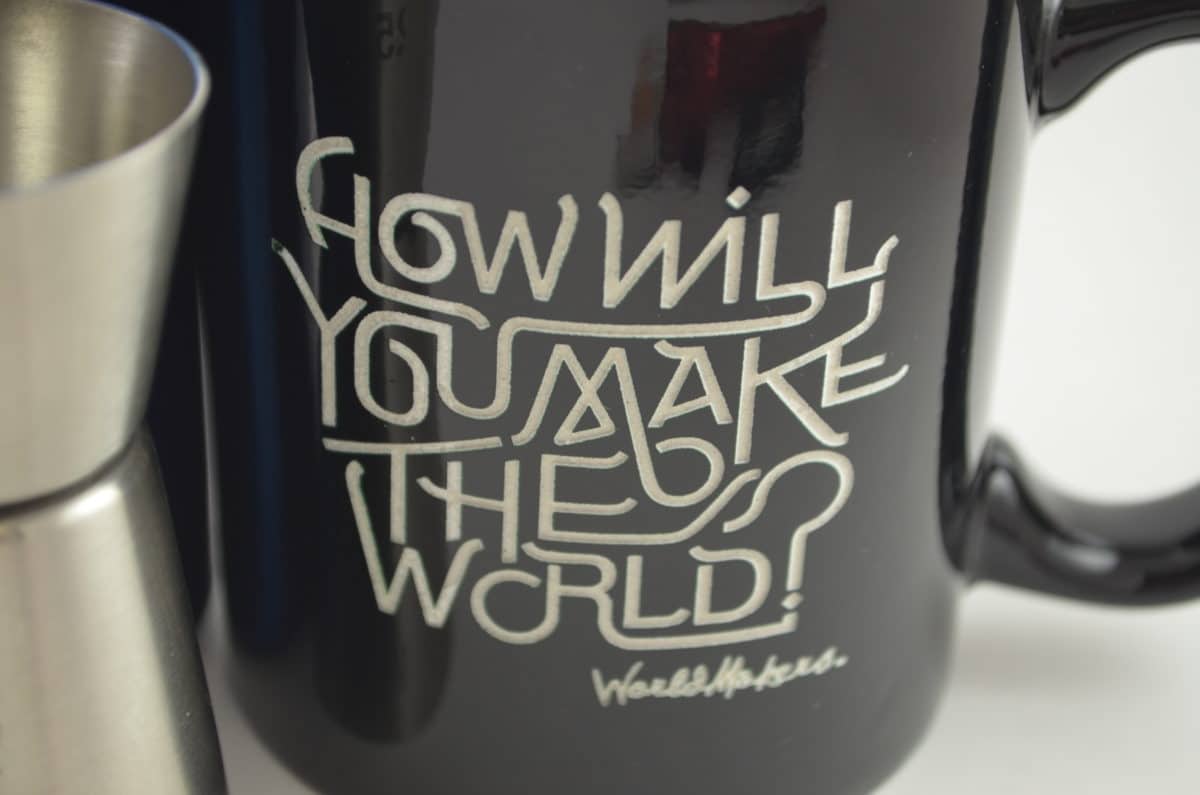

- You can add logos, bar codes, Mil-Std-130 UID, UDI, identification codes, lot codes, serial numbers, and more.

- Does not reduce the strength of the item.

- Makes products, parts and components easy to identify.

- There are no tools or moving parts and the beam can mark inside hard to reach areas of a part.

- The process is computer driven and controlled making it fast and accurate every time.

For a complete list of materials that we can process visit our Materials page.

Accubeam’s Laser Marking Services

Accubeam has over 15 years of experience and we are the market leading laser marking company with innovative tooling and processes to add value to our customer’s products. Our focus is on quality and customer service and our business prides itself on honesty and transparency.

We process both short run and large full production cycles, no job is to large or small. If you would like to view some examples you can view some laser marking pictures here.

If you have any questions about your parts, upcoming jobs or looking for general information, contact your local sales team with offices in Sarasota and Orlando.

We look forward to serving you.