DEEP LASER ENGRAVING

What is Deep Laser Engraving?

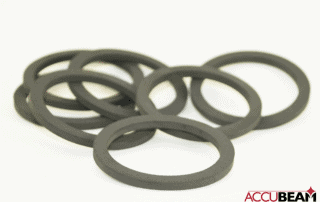

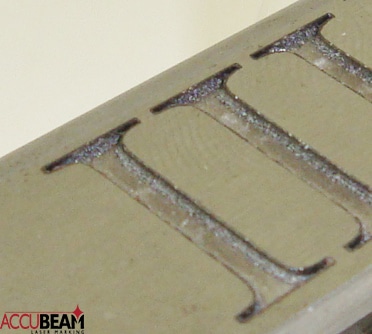

Deep Laser Engraving is a process by which a beam of focused light interacts with the surface material to vaporize or remove many layers leaving a cavity in the surface that is noticeable to the eye and touch. The amount of material removed and the depth of the cavity can be controlled by a skilled engineer to produce quality engravings in any material type.

Deep Laser Engraving vs. Laser Engraving or Etching

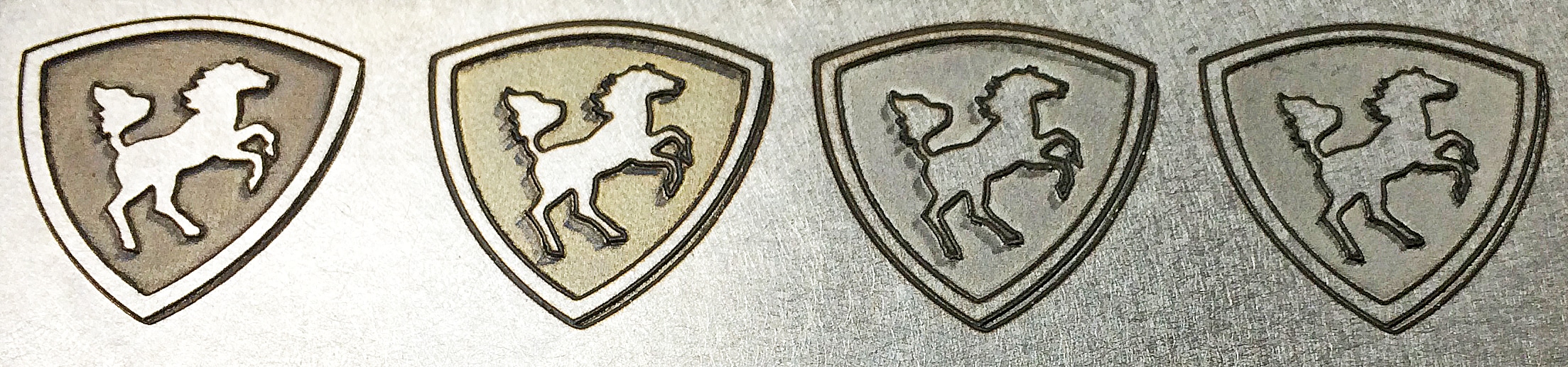

The difference between deep laser engraving and laser engraving/etching is a matter of depth and where the line falls is subjective based on the shop you are dealing with and the material to be engraved. Going .005” deep on aluminum is very different that doing it on titanium and both are different than stainless or tool steel. An operator must have the skill, experience and most importantly the right laser for deep engraving on that material because most lasers generate heat. Excessive heat while deep engraving will damage and potentially destroy a part thus choosing the right laser engraving service provider is crucial.

Not only can we reach the depth you need, we perform deep laser engraving measurements on all depth critical jobs and provide documentation if needed for quality purposes.

![]()

Why Accubeam Deep Laser Engraving?

- Accubeam can hit and hold depths in excess of .035” on flat or curved surfaces, inside radii and in locations unreachable by a CNC or other mechanical engraver.

- Deep laser engraving is available on all material types, including stainless steel and titanium.

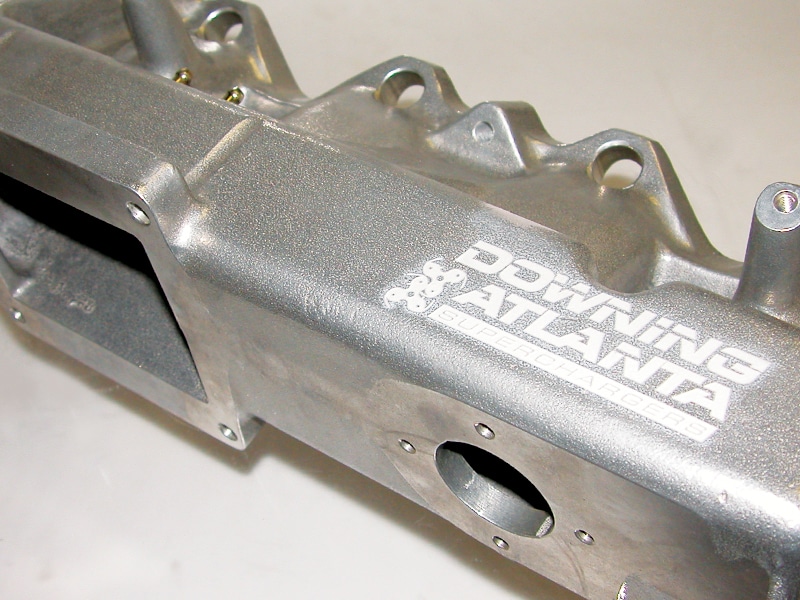

- Deep Laser Engraving is an efficient and economical solution for injection mold cavities, inserts, core pins, dies and many other applications.

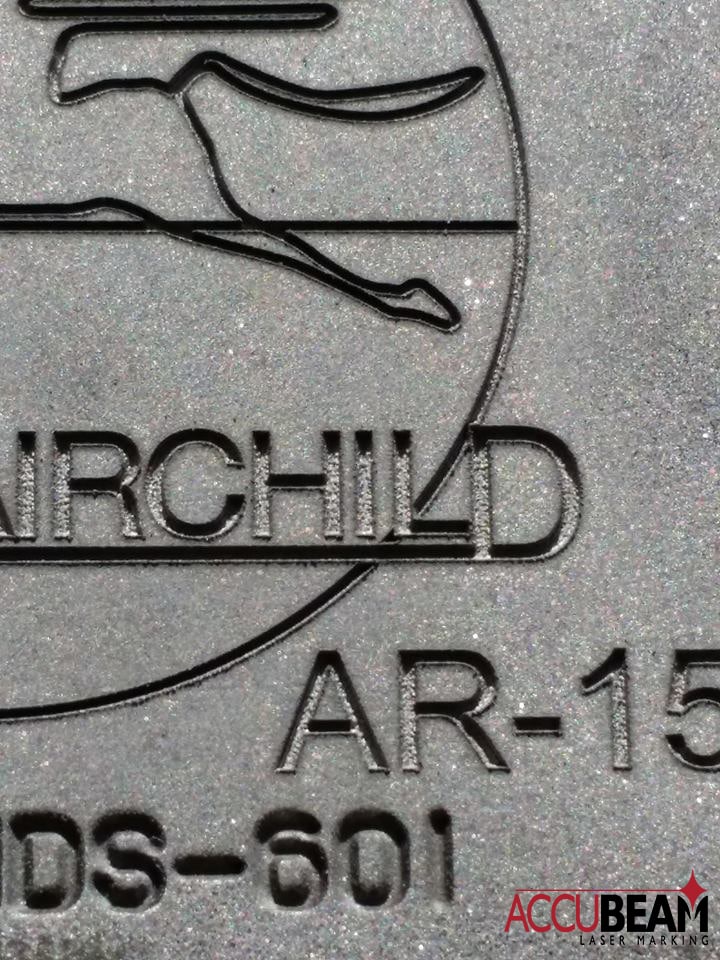

- The laser can produce any type of mark ranging from simple text to complex logos, shapes, barcodes and 2D Data Matrix Codes. Accubeam uses a high power laser with a spot size less than .003” that produces a superior mark on all metal types.

- Accubeam has an FFL for Manufacturers, which provides us the capability to receive, transfer and process assembled Class 3 Firearms including SBR and Suppressors. Typical engraving work for Class 3 Firearms includes Trust Engraving, logos and other operating marks.

- Laser engraving is permanent, able to withstand the harshest environments.

- The process is computer driven and controlled making it fast and accurate every time.

Accubeam has over 15 years of experience and we are the market leader in innovative tooling and processes to add value to our customer’s products. Our focus is on quality and customer service and our business prides itself on honesty and transparency.

We process both short run and large full production cycles, no job is to large or small.

Click here to view pictures of recent Deep Engraving Jobs at Accubeam.

If you have any questions about your parts, upcoming jobs or looking for general information, contact your local sales team with offices in Sarasota and Orlando.

We look forward to serving you.