IDENTIFICATION

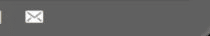

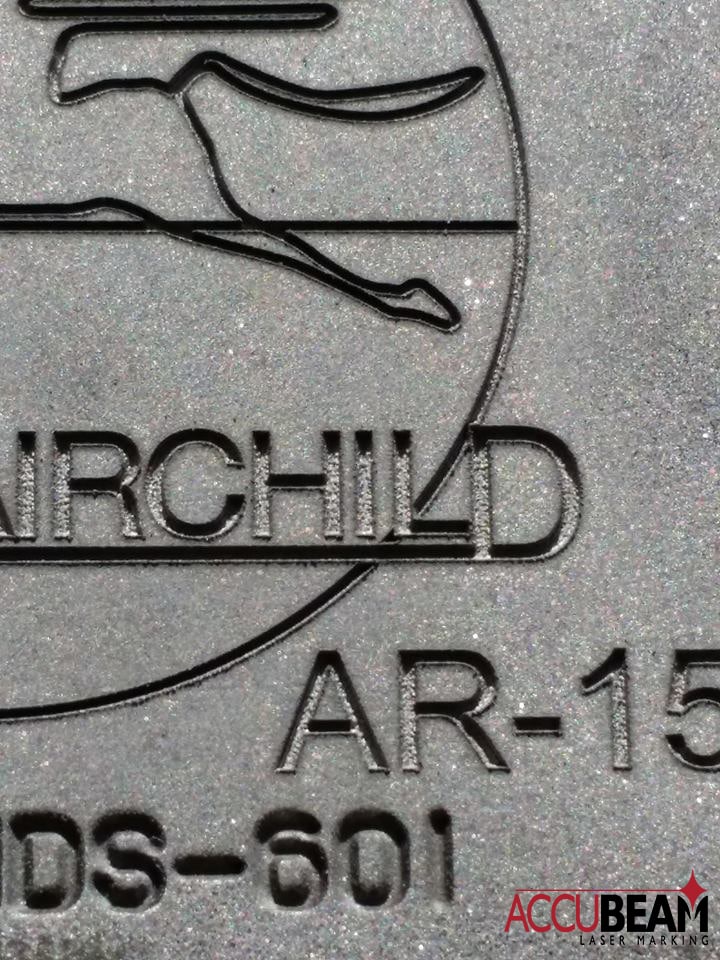

Laser Marking Identification is a method to permanately identify parts and components with part numbers, serialization, bar codes, lot codes or other unique markings relevant to the industry. There are a few different methods to add Identification Marks to parts. Direct Part marking is where the part is physically marked by the laser, either on a bare material surface and/or by removing a surface coating such as anodizing, powder or paint. ID Tags and Plates can be cut and colored to fit any size or location and can include pre-drilled holes for screws and rivets. TESA security labels are also an option. TESA labels can withstand harsh conditions and add a level of security.

Products and parts need to be identifiable and traceable for a variety of reasons, safety, inventory control, loss prevention, part identification and more. There are several mandates and/or requirements that require different industries to identify parts for safety purposes. Some of these include the aerospace, medical and automotive industries. For certain DOD asset acquisitions, a UID code is necessary and can be applied using the methods described above; direct part marking, tags/plates and labels. All UID marks come with a validation and grading report for quality verification purposes.

With Accubeam’s identification and coding services you can be assured that your parts and /or products will be easy to identify and conform to all applicable standards.

Here are some of identification services Accubeam can add to products and parts:

- Part Numbers

- Serial Numbers

- Time Stamps

- Bar Codes

- 2D Data Matrix and UID Codes

- Validation and Grading of Machine Readable Codes

- Date Codes

- Sequential Numbering

- Quick Response Codes (QR Codes)

Accubeam’s Laser Marking Identification and Coding Services

Accubeam has the knowledge, experience, and qualified staff to effectively laser identify and code your parts, components, assets and inventory items. If you would like more information about our services please contact us today at our Florida Sales Office.

We are here to answer your questions and we look forward to serving you.