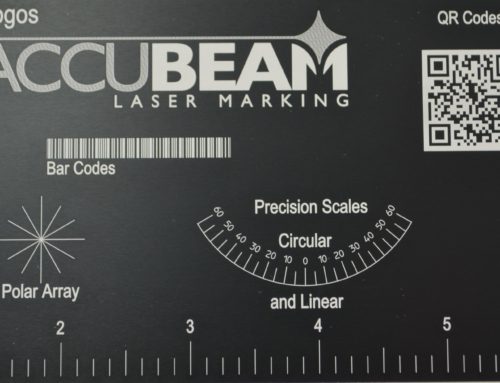

The preferred method of applying 2D UIDs is a type of Machine Readable Medium called a 2D Data Matrix ECC 200 Symbol, and requires a verification process to ensure the UID meets the MIL STD 130 requirements. Additionally, once a UID code has been created and place on a product provided to the US DoD, that unique string must be entered into the IUID Registry. This registry is the single source of data tracking all assets meeting the minimum criteria that are sold to the US DoD.

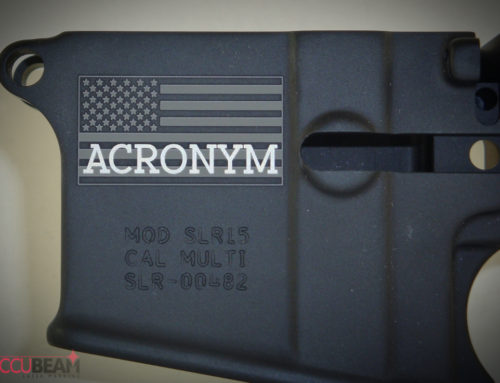

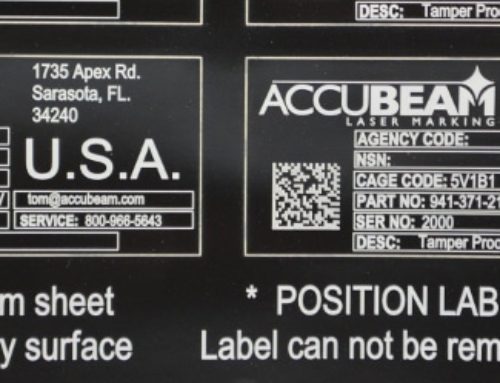

The preferred tool to apply a 2D UID is with the use of a laser. Lasers provide a permanent mark that can withstand the test of time and wear which is essential for military applications. Accubeam Laser provides services to apply the 2D UID directly to a part or on product tags that can be affixed to your products during the production cycle. Contact Accubeam via phone or the Request a Quote option at the top of the page to learn more about the process.

Next up on our Popular Questions and Answers Series: “I keep hearing about 2D Grading, what does that mean?”