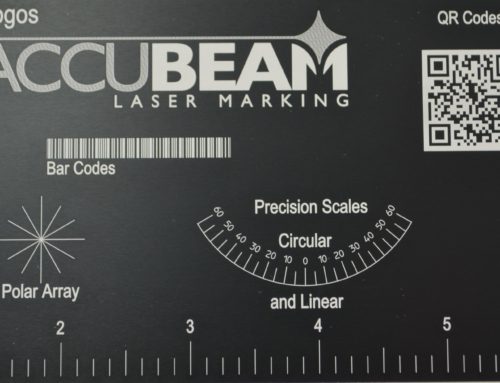

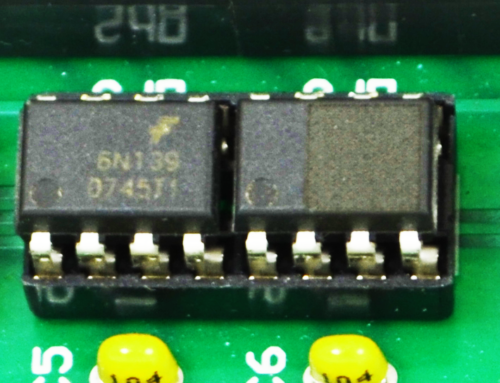

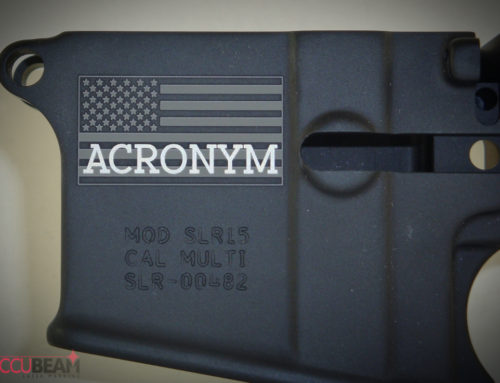

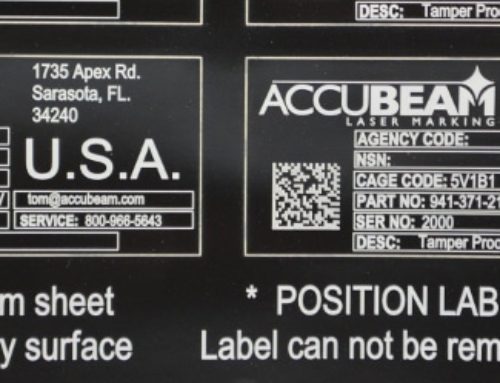

Laser cutting is a fabrication technique that’s well-suited for applications requiring high precision and accuracy. As an experienced provider of laser cutting services, Accubeam serves the military industry with components that not only meet MIL-SPEC standards but reliably withstand extreme environmental conditions. For any branch of the military, our laser-cut parts meet performance, budget, and lead-time requirements.

Military and Defense Applications

Whether on the ground, in the air, or in the sea, laser-cut parts are used to create components for all branches of the military. One common application is high-stress armor plating for military vehicles like the HMMWV (Humvee). No matter what the intended end use is, military components must deliver reliable performance even under harsh environmental conditions. In these demanding applications, military-grade laser-cut parts meet these requirements.

Because laser cutting achieves such high levels of precision, it ensures the utmost material efficiency. This not only reduces waste and material costs but also minimizes the risk of defects and failure in the components themselves. In military cutting applications, the high level of precision that laser cutting delivers meets MIL-SPEC and other stringent requirements. Additionally, compared to other fabrication methods, laser cutting offers reduced downtime between tasks, allowing for products to be finished as quickly as possible.

Military Applications

At Accubeam, we offer a comprehensive range of laser-cutting techniques and process both large and small-scale production runs. As laser-cutting specialists with over 15 years of experience, we help our military customers address the unique material and environmental challenges these applications involve. Whether you need to produce a single component or a full production run, our robust laser-cutting systems can meet your requirements, with fast turnaround times.

Advantages of Laser Cutting for Military Manufacturing

The laser cutting process offers the following benefits for military manufacturing:

- Tight tolerances. Our laser cutting equipment achieves tolerances of ±0.002 in. for metal, plastic, and fabric components. This capability enables the production of highly uniform end components, which is especially ideal for military applications, as well as large-volume orders in general.

- Intricate design capabilities. Laser cutting performs multiple cuts without the need to change tools, making it an ideal solution for cutting complex designs and different shapes within the same material thickness.

- Cost-effectiveness. Since materials are melted or vaporized during the laser cutting process, the result is clean, accurate components. Defects such as burrs or warping are rarely an issue with laser cutting, greatly reducing the need for costly tooling and additional finishing processes that could hinder production.

- Speed. Compared to other cutting techniques, laser cutting is a much faster process. This makes it particularly suitable for making complex cuts.

- Safety. Because laser cutting is a non-contact process, it greatly reduces the risk of accidents.

At Accubeam, our advanced laser cutting equipment enables us to deliver higher quality parts faster, and at an affordable price. Whether you need to develop a prototype or obtain a large production run on a tight timeline, our team can meet your needs. We specialize in helping customers develop high-quality parts that do not require additional tooling.

Laser Cutting for Military Manufacturing Materials

Laser-cut parts from Accubeam are manufactured to meet your design standards for precision and complexity. We work with a wide range of materials, including:

- Aluminum, brass, bronze, copper, and other non-ferrous metals

- Armor plating

- Stainless steel

- Inconel

- Mild steel, high-strength steel, and galvanized steel

- Titanium

- Ceramic

- Rubber, plastic, foam, and acrylic

- Wood and mylar

As a leader in laser cutting technology, we serve military and defense applications with the highest level of precision and accuracy. We are capable of cutting all types of metal substrates, in thicknesses that vary depending on the metal.

Military Laser Cutting from Accubeam

Compared to other fabrication methods, laser cutting provides the unrivaled accuracy and precision that are required in military cutting projects. As the market leader in innovative tooling, Accubeam creates high-performance military components that comply with all industry regulations. Visit our laser cutting page to learn more about our technology and services, or our military page for more information on how we serve the military industry. If you’d like to get started on a project, contact our team or request a quote today.