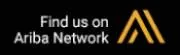

Laser Cutting and Laser Marking in the Aerospace Industry

Laser technology is widely used in many industries for cutting, etching, marking, and engraving many types of materials. For the aerospace industry, lasers offer precision cuts that are clean and smooth, requiring little to no additional finishing. They are computer controlled, and move quickly for high-speed production with minimal human error or waste.

Learn more about Accubeam’s expertise using lasers for cutting and engraving for many types of materials and critical aerospace applications.

Key Applications of Laser Cutting in Aerospace

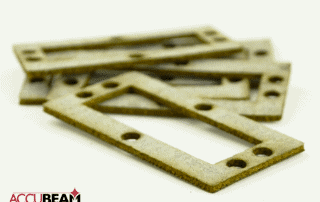

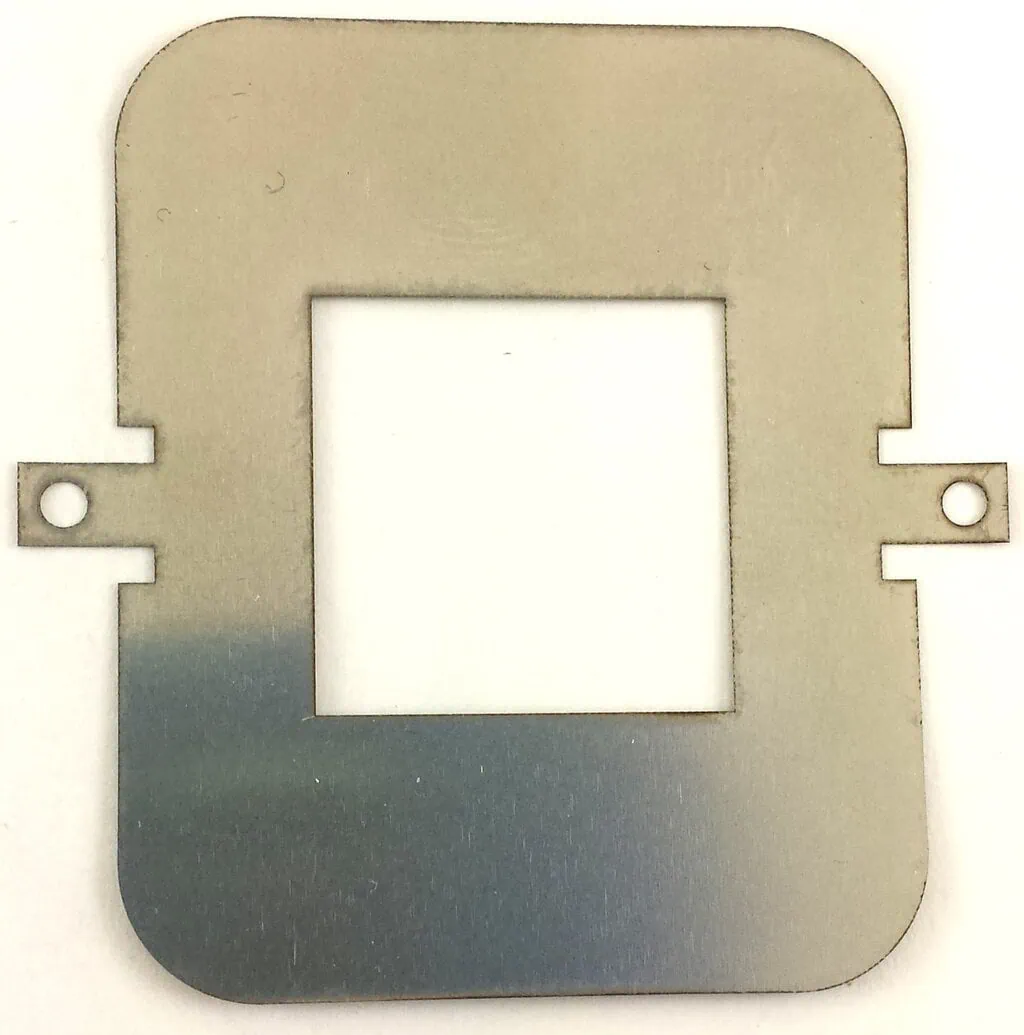

CO2 and fiber lasers can be used to cut metals including aluminum alloys and titanium, as well as non-metallic composite materials. Here are some examples of common laser cut components:

- Aircraft Parts. Laser cutting is a computerized process, in which a CAD file is used to guide the cutting head for flat and curved pieces such as fuselage panels, wing ribs, and engine parts. Drilling holes of precise diameter and placement on aircraft parts is another operation lasers are used for.

- Satellite Components. Laser cutting is ideal for fabricating intricate satellite components like antennas and structural supports to ensure reliable and consistent performance.

- Rocket Parts. Rocket parts like nozzles and fairings are made of durable materials and must be manufactured within tight tolerances. High-precision lasers cut these and other critical parts quickly and reliably.

- Tools and Fixtures. In addition to end-use parts, laser cutting can be used to produce tools and fixtures used in manufacturing other aerospace components.

Laser Marking in Aerospace Applications

Lasers can also be used to permanently mark parts with important information such as:

- Serial numbers

- UID and MIL-STD-130 identification

- AS478 markings

- Barcodes

- Lot codes or numbers

- Tracking information

- Branding or logos

- Model numbers

- Production dates

- Regulatory marks

- QR codes

Depending on the type of marking required, etching, engraving, or carbon migration processes can be used to create high-contrast, clear, easy-to-read markings on components. Some examples include:

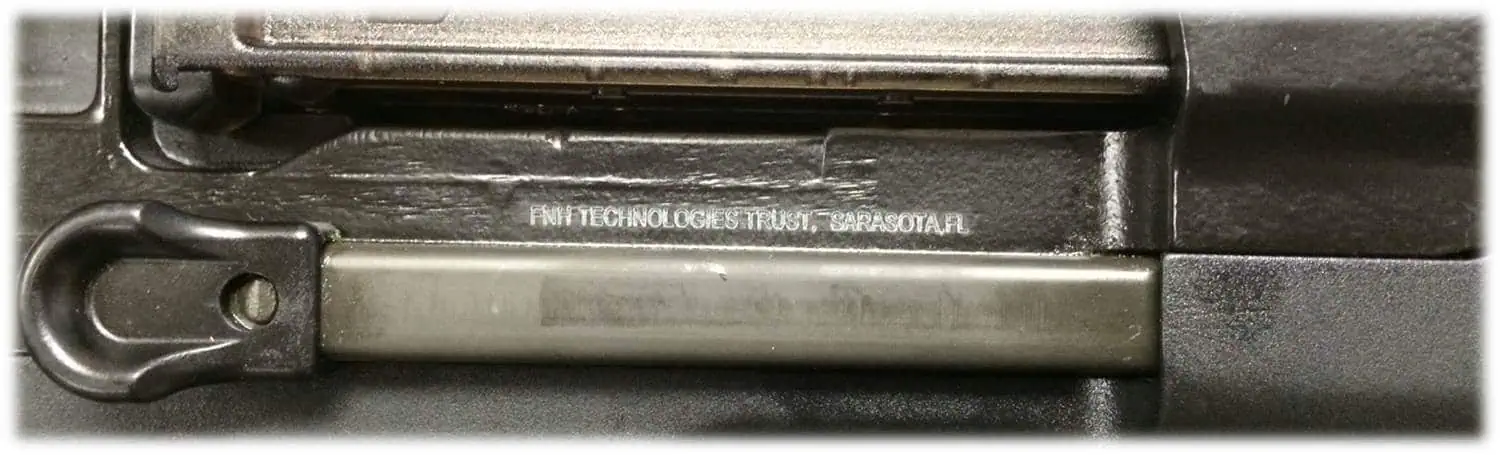

- Component Identification. Permanent laser markings make it easy to label and identify parts and batch numbers. This traceability improves quality control and facilitates maintenance throughout the component’s lifecycle.

- Barcodes and QR Codes. Lasers can make intricate or complex designs, such as barcodes, QR codes, and other distinguishing marks used for inventory management and organization.

- Data Matrix Codes. This compact coding system can be used to mark small aerospace components with large amounts of data to support traceability, even for parts that are constrained by limited space.

How Laser Cutting and Engraving Benefit Aerospace

Laser cutting and marking offer several advantages for aerospace applications, including:

- Improved Precision. Because the laser is automated by a computer and CAD file, the position of the laser is exact and variation between finished parts is minimal.

- Damage-Free. In contrast to other marking and cutting methods, lasers are non-contact, with a small heat-affected zone (HAZ). This greatly reduces the risks of damage or deformity of the component due to physical force, warping, or scorching.

- Enhanced Efficiency. Lasers follow a pre-programmed cutting path so movements can be quick and efficient. Cutting paths are designed to use material efficiently so that many components are produced using as little material as possible. Because the laser vaporizes material as it cuts, edges tend to be clean and smooth, eliminating the need for additional finishing processes like grinding or deburring. All of these save time and money in manufacturing.

- Versatility. Lasers can cut, engrave, or drill a variety of materials, including aluminum alloys, titanium, steel, composites, polycarbonate, and other non-metallic materials commonly used in the aerospace industry.

- Reduced Waste. Laser cutting uses material efficiently, which results in less wasted material. Automated, highly repeatable cuts mean that parts are within tolerances throughout the batch, for fewer scrapped or reworked parts.

Aerospace Industry Laser Cutting from Accubeam

Accubeam has comprehensive laser cutting and engraving capabilities that support aerospace applications, including:

- Flame Cutting. With this technique, oxygen is used to remove melted material from the kerf (i.e., the space created in the material by the laser), creating an exothermic reaction that adds heat and improves efficiency.

- Fusion Cutting. This process uses inert gases, instead of oxygen, that will not react with the material to accelerate the cutting process.

- Sublimation Cutting. In this process, when the laser vaporizes the material, an inert gas is used to blow away the excess.

- Laser Drilling. Lasers can be used to drill holes in precise sizes and locations on parts with a series of pulses of the laser.

- Nd:YAG laser cutting. Solid-state yttrium aluminum garnet lasers are doped with neodymium ions and emit a wavelength readily absorbed by “reflective” metals like stainless steel, carbon steel, aluminum, brass, and copper.

- UV laser engraving, ablation, and drilling. These lasers have a highly concentrated beam that can engrave or erode the surfaces of materials, including transparent materials like glass. They can be used for precision drilling.

Contact Accubeam Today for High-Quality Laser Cutting

Accubeam is an industry leader in aerospace laser cutting and laser marking processes. We bring years of experience with aircraft components and tooling to each project, and our customers can expect the highest quality from our work.

Contact us to learn more about our laser cutting and laser engraving services, or request a quote for your next project.